Premier Pleat Polypropylene

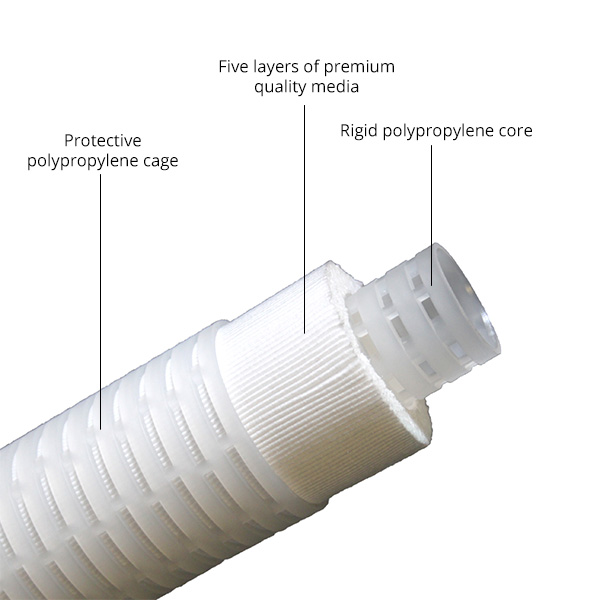

Constructed from FDA compliant media, the multi-layered PPP consistently and effectively removes the desired particle size, whilst still allowing finer particles through. A high performance cartridge, the all polypropylene construction give the premier pleat range wide application suitability.

The inert properties of the all polypropylene constructed PPP mean it is suited for a wide range of applications where chemical compatibility and product dependability are paramount.

The multi-layered media delivers a reliable pleated cartridge range that provides exceptionally sharp cut-offs for consistent particle removal.

Manufactured from a technically advanced media capable of effectively and consistently removing the desired particle size, whilst allowing finer, nondamaging particles through, maximising filter life and ensuring dependable particulate separation.

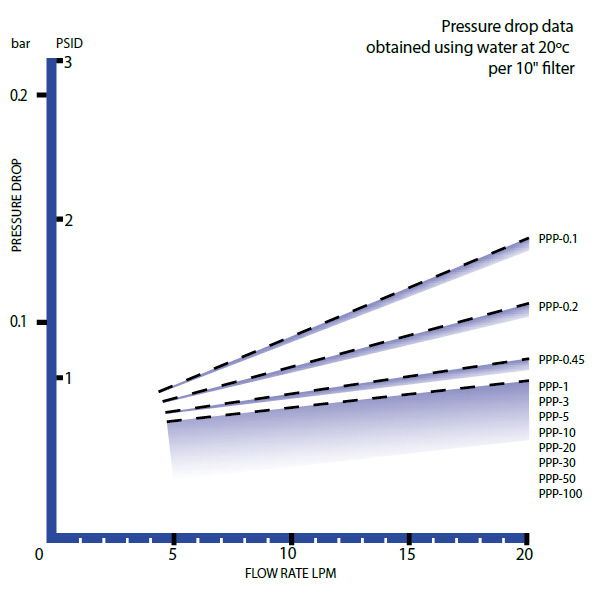

A large surface area (0.6m2 per 10"), up to 50% more than other industry comparable cartridges, ensures the Premier Pleat polypropylene delivers superior flow rates and higher dirt-holding capabilities.

Features & Information

- Superior media surface area of 0.6m2 ensures superior flow and higher dirt-holding capacities of up to 50% more than some other industry comparable cartridges

- Sharp cut-off characteristics created by the superior media ensure dependable particle removal of the size required, therefore maximising filter life and application integrity

- FDA compliant media offering 11 micron sizes, 6 standard length options and 9 end cap choices, this range is versatile in its application suitability and capabilities

- Thermally-bonded ensuring no leaching of adhesives into the filter stream, particularly important for certain applications such as food and beverage

- Extensive chemical compatibility is achieved with all-polypropylene construction

Layers

| Coarse outer prefiltration layer |

|

| Finer secondary prefiltration layer |

|

| First polypropylene main filtration layer |

|

| Finer secondary polypropylene main filtration layer |

|

| Postfiltration support layer |

|

Product Performance

Applications & Industries

- Pre or final stage filtration of general water applications

- Beverage applications requiring purification or clarification

- Hospitals where secure seals are required and cartridge integrity is important

Ordering Details

| Product Code | Micron (μ) | Standard Diameter Lengths (") | End Caps | Seal Material | ||

|---|---|---|---|---|---|---|

| PPP |

0.1, 0.2, 0.45, 1, 3, 5, 10, 20, 30, 50, 100 |

4⅞ | AA, CG |

STANDARD SILICONE = S OPTIONAL EPDM = E VITON = V |

||

| 9¾ , 10, 20, 30, 40 |

AA, CG, EG, EH, FG, FH, MH, QG, ZH |

|||||

| Packaging | 4⅞" | 9¾" | 10" | 20" | 30" | 40" |

| 24 at 5kg | 24 at 9kg | 24 at 9kg | 12 at 9kg | 12 at 13kg | 12 at 18kg | |

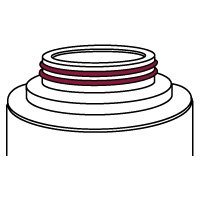

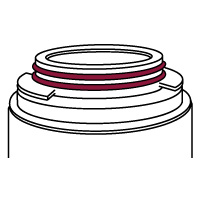

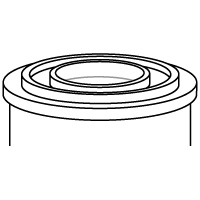

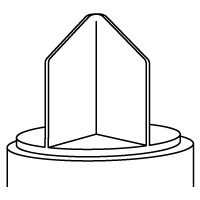

End Cap Options

|

|

|

|

|

|

| A - Open end | C - 213 |

E - 222 M - 224 Q - 222 SS insert |

F - 226 Z - 226 SS insert |

G - Closed end | H - Fin |

| Retention Efficiency % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pore Size | 0.1μ | 0.2μ | 0.45μ | 1μ | 3μ | 5μ | 10μ | 20μ | 30μ | 50μ | 100μ |

| 0.1μ | 95 | 96 | 98 | 98+ | 99 | 99+ | |||||

| 0.2μ | 93 | 95 | 97 | 98 | 98+ | 99+ | |||||

| 0.45μ | 82 | 83 | 96 | 97 | 98 | 99 | 99+ | ||||

| 1μ | 80 | 82 | 94 | 96 | 97 | 98 | 99 | 99 | 99+ | ||

| 3μ | 30 | 59 | 82 | 86 | 97 | 97+ | 98+ | 98+ | 99 | 99 | |

| 5μ | 47 | 90 | 97 | 98 | 98+ | 99 | 99 | 99 | |||

| 10μ | 30 | 57 | 98 | 98 | 98+ | 99 | 99 | ||||

| 20μ | 29 | 56 | 91 | 98 | 98+ | 98+ | 99 | ||||

| 30μ | 28 | 55 | 90 | 97 | 98 | 98 | 98+ | ||||

| 50μ | 26 | 54 | 89 | 96 | 97 | 97+ | 98+ | ||||

| 100μ | 29 | 48 | 89 | 94 | 98 | ||||||

| Particle removal efficiencies are determined using AC Fine Test Dust dispersed in water at a constant flow rate up to a differential pressure of 2.75 bar | |||||||||||

Product Specification

| Material of Construction | POLYPROPYLENE |

| Maximum Temperature | 82°C |

| Filter Lengths (") | 4⅞, 9¾, 10, 20, 30, 40 |

| Micron Ratings (μ) | 0.1, 0.2, 0.45, 1, 3, 5, 10, 20, 30, 50, 100 |

| Supplier | Aquarit |